Having been engaged in manufacturing visualization for years, my deepest insight is that the "expression dilemma" of complex machinery was once the biggest barrier to communication in the industry. When I first entered the profession, I worked with the team to interface with clients on an energy storage project. Despite 20 pages of 2D assembly drawings and 4 hours of on-site disassembly and explanation, the client still had a vague understanding of the cell arrangement logic and heat dissipation circuit direction of the liquid-cooled energy storage cabinet. When bringing energy storage module samples to exhibitions, the bulky cabinet could neither display the wiring details of the internal Battery Management System (BMS) nor simulate the thermal management dynamics during charging and discharging. We missed cooperation opportunities many times in distributed energy storage project tenders due to "unclear technical expression". It was not until I came into contact with industrial 3D animation that I realized that the complex systems of energy storage equipment could "speak", and abstract thermal management principles and cell balancing logic could be transformed into intuitive images, which strengthened my determination to delve deeper into visualization in the energy storage field.

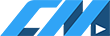

CMuse 3D Animation Works Project Display Images

In years of practical operation, camera animation, growth animation, and deformation animation have been my most commonly used "combination punches". They each play their roles and can work together to solve complex scenarios. Camera animation is like my "virtual camera"; through pushing, pulling, panning, and tilting, I can balance the overall view and details. When making a demonstration for a hybrid mixer, I use a forward-pushing shot to focus on the 0.01mm meshing gap of the paddles, and then a backward-pulling shot to show the overall layout of the machine in the workshop, allowing clients to clearly see the "precision" and "adaptability" at a glance.

Growth animation is a powerful tool for disassembling processes. When making demonstrations for automated production lines, I make robotic arms and conveyor belts "grow step by step" according to the assembly sequence, turning complex installation steps into logically clear visual sequences that are easier to understand than text manuals.

Deformation animation, on the other hand, is the "magic" for presenting physical principles. Previously, when making a demonstration for a desulfurization tower for an environmental protection equipment enterprise, I used deformation animation to simulate the flow trajectory of the spray liquid, intuitively showing the impact of angle adjustment on desulfurization efficiency, and the client finalized the optimization plan on the spot. Later, I found that integrating the three technologies yields even better results. When creating animations for new energy battery production lines, I used camera pushing and pulling to switch between the overall view and close-ups, simultaneously using growth animation to display component assembly, and deformation animation to present fluid flow. This not only allowed clients to see the 1.2m/s conveyor belt efficiency but also gain insight into the precise operation of the robotic arm's 50N gripping force, doubling communication efficiency directly.

CMuse 3D Animation Works Project Display Images

Over the years, I have undertaken animation projects across all scenarios including R&D, production, marketing, and after-sales, and have personally witnessed how industrial 3D animation has become an "invisible engine" for cost reduction and efficiency improvement in the energy storage industry. The pain points of traditional paper manuals are particularly prominent, especially in installation scenarios.

Pylontech once reported that the installation manual for its L2200 OMNI integrated liquid-cooled energy storage cabinet was as thick as 46 pages, containing more than 200 technical parameters. Due to the inability to understand professional requirements such as "cable trench depth ≥ 0.8m" and "M10 bolt torque 45±3N·m", overseas installation teams repeatedly encountered problems such as poor sealing of liquid-cooled interfaces and excessive grounding resistance. A European project was delayed by 8 days in grid connection due to installation deviations, resulting in direct losses of over 200,000 yuan.

To address this pain point, I customized an "animated installation manual" for Pylontech, converting abstract parameters into visualized operations. For the core difficulties in liquid-cooled system installation, close-up camera shots were used to show the 15±2N·m torque tightening process of double ferrule joints, and dynamic annotations were used to present the 0.8MPa pressure holding for 30min airtightness test standard. For the container levelness calibration link, the detection process of the laser level was simulated through animation, clarifying the practical specification of "levelness ≤2mm/m", and even marking the detailed steps of "diagonal tightening completed in three times".

Pylontech's technical team reported that after the launch of the animated manual, the one-time pass rate of overseas installations increased from 72% to 96.8%, and the training cycle was shortened by 50%. In just half a year in the European region, rework costs were reduced by more than 1.2 million yuan. One installation engineer said: "Following the animation step by step, there is no need to flip through the manual to check parameters, and even newbies can handle high-precision installation."

On the R&D front, I also used animation to optimize product design for Pylontech. Through Unreal Engine's physics engine to simulate the thermal management dynamics of the L3300 BAT battery system, the impact of cell cluster spacing on heat dissipation efficiency was intuitively presented, helping the R&D team adjust the layout scheme. This enabled the system to control the temperature difference within 8℃ when operating in the wide temperature range of -30℃ to 60℃, meeting the stringent requirements of international certifications such as IEC and VDE, and avoiding mold rework costs caused by design iterations.

In marketing scenarios, the animated installation manual has become an "added bonus". At the World Energy Congress in Dubai, Pylontech used the 3D animation I created to demonstrate the "plug-and-play" installation process of the energy storage cabinet on-site—from container fixing and module splicing to the precise docking of PCS and transformers. The 12-minute animation clearly presented the entire process of "installation - commissioning - grid connection". Compared with competitors' paper manuals, clients could more intuitively feel the installation convenience of Pylontech's products, and immediately reached agent cooperation intentions with three countries on the spot, helping to secure overseas orders exceeding 180 million yuan.

In after-sales training, the value of animation is also significant. Pylontech's overseas after-sales team adopted a VR + animation training model to simulate the troubleshooting processes of common faults such as liquid-cooled circuit leakage and excessive cell voltage difference in advance, improving troubleshooting efficiency by 40%. For an energy storage system fault in an Australian mining project, the maintenance team completed the repair in only 2 hours according to the animation guidelines, while it would take at least 6 hours under the traditional model. This made me deeply realize that animation is not only an "installation guide" but also a "cost-reduction tool" throughout the product's full lifecycle. It standardizes and visualizes complex technologies, clearing communication barriers for energy storage enterprises' global layout.

CMuse 3D Animation Works Project Display Images

After doing animation for a long time, I deeply understand that manufacturing clients value both "high precision" and "cost-effectiveness". Over the years, I have been using technological innovation to optimize processes: real-time rendering technology allows me to adjust parameters on-site with clients—conveyor line speed and robotic arm angle can be modified at will. Previously, adjustments that took 2 weeks can now be completed in 1 day, ensuring that the animation is completely consistent with the production site. I also built my own modular material library with more than 1,000 industrial models, and parameters such as gear tooth number and conveyor belt width can be flexibly adjusted. Previously, when making production line animations for new energy enterprises, the material library reduced modeling time from 3 weeks to 1 week and cut costs by 33%.

Of course, precision is the bottom line. When making mechanical animations, I strictly follow the Mechanical Design Manual; the gap of Grade 6 precision gears must be controlled within 0.01mm. When making chemical animations, pipeline colors are marked in accordance with the Code for Design of Chemical Plants—red represents high-temperature media and yellow represents flammable media, ensuring that the animation is not only "good-looking" but also "compliant" and "accurate". Later, the introduction of AI-assisted modeling technology further improved efficiency. Previously, modeling for lithium battery animations took 10 days, but now it can be completed in 7 days with a deviation from experimental data of no more than 2%.

From initially simply thinking that "animation can solve communication problems" to now deeply understanding its value across the entire manufacturing chain, I am more convinced that industrial 3D animation is not a simple "technical show-off" but a "bridge" connecting technology and value. It makes complex machinery "understandable at a glance", makes R&D more efficient, production smoother, marketing more powerful, and training simpler. Over the years, I have watched the global industrial visualization market scale expand continuously and witnessed more and more enterprises improve their core competitiveness through animation. This has further strengthened my direction—continue to delve deeper into technology and provide more accurate, efficient, and cost-effective industrial 3D animation to contribute to the high-quality development of manufacturing.

Welcome to further explore the professional service system of CMuse3D, and look forward to your messages and inquiries. We will provide high-quality standards and professional service levels equivalent to European counterparts at an affordable price of only one-third of the European market, helping your projects achieve high-end presentation.

Contact Us

Leave your contact information, and we will arrange a representative to get in touch with you.